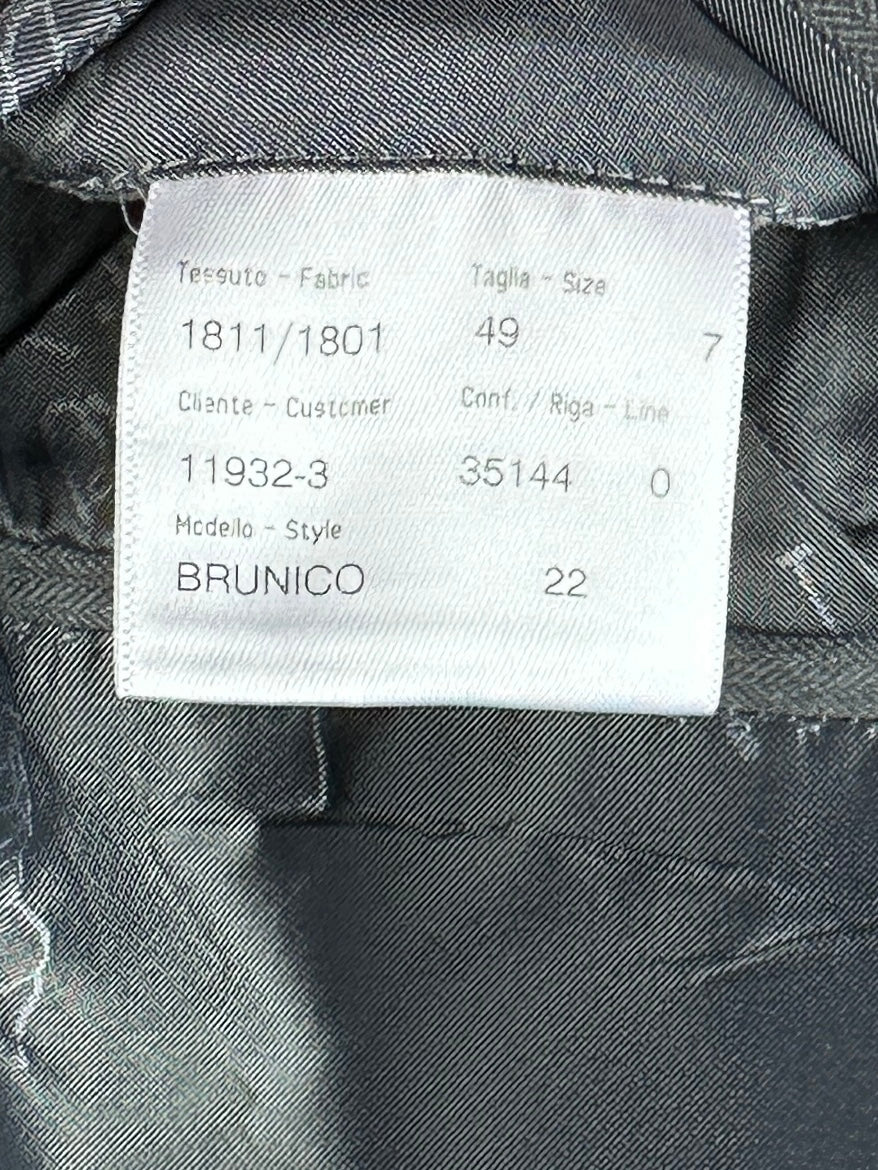

Brioni Grey Super 150's Three-Piece Suit

49 IT / 39 US / Medium Long

Dress to impress with the Brioni Grey Super 150's Three-Piece Suit, featuring an understated herringbone pattern that exudes sophistication. Meticulously crafted, this suit showcases the pinnacle of luxury and style. Made from the finest Super 150's wool, it offers unmatched comfort and a tailored fit that is second to none. Discover the elaborated sartorial details below.

Each Brioni garment is crafted using the Brioni method, a custom process with 220 steps and more than 22 hours of workmanship.

Composition: 100% Super 150's Wool

Color: Grey

Pattern: Herringbone

See how we measure our sartorial items

Discover the customization possibilities by visiting our tailor alteration guide

Shipping

- Complimentary shipping on orders over €200 (Netherlands), €500 (EU), and €1,000 (rest of world).

- Orders under these amounts: shipping rates depend on your country.

- Customs duties or import fees may apply and are the customer’s responsibility. The courier may charge additional fees.

Returns

- You have the right to return your order within 14 days of delivery.

- If you wish to return an item, please notify us within 48 hours of receiving your order.

- Return shipping is at the customer’s expense.

- A 10% restocking fee will be deducted from your refund for all returns.

Please carefully review all measurements and quality control notes in the listing before purchasing. Return shipments have an environmental and economic impact. For any questions or if you need help, feel free to contact us before placing your order.

General Note: While we inspect each item to ensure its quality, please note that minor imperfections may be present due to the preloved nature of the garments. We strive to represent every item accurately, but subtle signs of wear may sometimes go unnoticed. We appreciate your understanding and commitment to sustainable luxury.

Choose options

Discover the

Sartorial Details

Full Canvas Construction

A sartorial jacket - or coat - needs an interlining that will help give it shape and mold it. Canvas gives the item a tailored and crafted look. In short, it breathes life into it. Purely technical, canvas is made from either horsehair, wool, mohair or camel hair. It could also be a mix of them all, with varying thickness and weight. The canvas is stitched to the jacket, often by hand, thus making the canvas pieces 'floating' in the middle of the inner and outer cloth. This gives the jacket added flexibility. The canvas runs from the upper parts, all the way down to the end of the jacket. After you wear your canvassed suit for a while, it will begin to take your shape and look incredibly natural.

Roman Style Shoulders

Characterised by a clean, strong silhouette, the Roman style has its origins in the military and equestrian style on Savile Row. While the heavily structured, military-inspired suits with strong shoulders and stiff canvassing were fitting of English nobles, the staid style was not an adequate reflection of the Italian way of life. As Italian tailoring grew into its own, though, different styles began to develop. In Naples unstructured whimsical Neapolitan suiting took hold. In Rome, where Brioni was born, the style evolved more subtly. The structured British style was made more voluminous, body conscious, and free-flowing without losing too much of the signature Saville Row shape.

Handmade Buttonhole

Handmade buttonholes are made using a chain of knotted loops called purl stitches that make them strong and visually distinctive. It takes about five seconds to sew a regular buttonhole with a machine – a single handmade buttonhole takes about 10 minutes to sew.

Two-Button Closure

The jacket has a two-button closure which keeps the profile neat.

Chest pocket - Rounded welt pocket

Also known as ‘barchetta’ Italian for ‘little boat’, it is so named because this pocket floats on the chest gently angled upward, just like the bow of a sailboat. These pockets echo the lively roll of a lapel that carries the spring of canvas and natural wool, unlike machine-made chest pockets that have a more stamped-out, rectangular shape and less life.

Darts

The tailors adds two darts - think of them as pinched seams - to ensure the jacket’s body achieves a slim silhouette. The process, called mezzo punto riprese, is done entirely by hand.

Kissing Buttons and Handmade Buttonholes

Also known as stacked buttons or waterfall buttons, kissing buttons are associated with Italian tailoring as Italian tailors make their jacket sleeve buttons in the kissing style. In this style, buttons touch each other and overlap one another. Handmade buttonholes; Even this step, apparently the simplest, is treated with an abundance of detail. Attaching the buttons is a job that requires patience and must be completed to perfection.

Flap Pockets

This was originally supposed to keep debris from getting into jacket pockets when worn in the country. Flap pockets occupy a sort of middle ground in terms of formality: they are the main choice for business suits, but they can also appear on sport coats as a testament to their casual origins.

size

49 IT / 39 US / Medium Long

Curator's Description

Curator's Description Materials

Materials