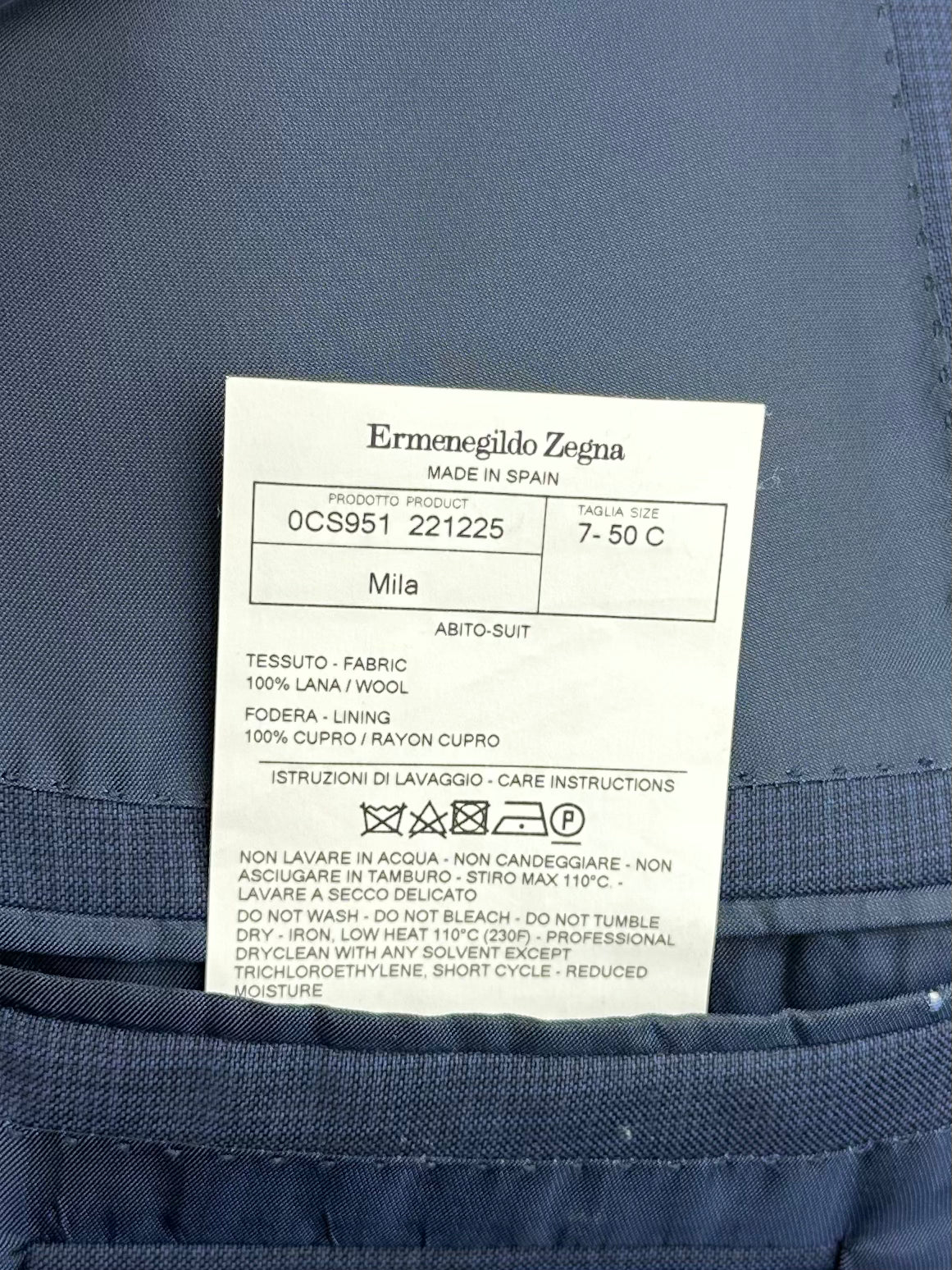

Ermenegildo Zegna Blue Trofeo Jacket

50 IT / 40 US / Large

This style is instantly recognizable by connoisseurs; notch lapels, milanese buttonhole, soft shoulders and rounded pattern below the profile of the jacket which accentuates a slim waist. Trofeo™ wool is a superfine Australian Merino wool characterised by longer and more elastic fibers that make garments smoother and more comfortable. Discover the elaborated sartorial details below.

By the time a Ermenegildo Zegna garment ends up hanging in an enthusiasts wardrobe, more than 500 hands will have touched it. They start their work by shearing the wool, weaving it, bundling it, dyeing it, knitting it, ironing it, cutting it, sewing it, ironing it again (and again). In Trivero, Piedmont, Zegna turns wool into cloth, and then sends it to the artisanal suit factory at Stabio, on the Swiss side of the Italian border, where the cloth becomes a tailored garment. What is thought to be simple is actually difficult, and what is thought to be done by machine is basically done by people, at a sophisticated level.

Composition: 100% Trofeo™ wool

Color: Blue

Pattern: Plain

See how we measure our sartorial items

Discover the customization possibilities by visiting our tailor alteration guide

Shipping

- Complimentary shipping on orders over €200 (Netherlands), €500 (EU), and €1,000 (rest of world).

- Orders under these amounts: shipping rates depend on your country.

- Customs duties or import fees may apply and are the customer’s responsibility. The courier may charge additional fees.

Returns

- You have the right to return your order within 14 days of delivery.

- If you wish to return an item, please notify us within 48 hours of receiving your order.

- Return shipping is at the customer’s expense.

- A 10% restocking fee will be deducted from your refund for all returns.

Please carefully review all measurements and quality control notes in the listing before purchasing. Return shipments have an environmental and economic impact. For any questions or if you need help, feel free to contact us before placing your order.

General Note: While we inspect each item to ensure its quality, please note that minor imperfections may be present due to the preloved nature of the garments. We strive to represent every item accurately, but subtle signs of wear may sometimes go unnoticed. We appreciate your understanding and commitment to sustainable luxury.

Choose options

Discover the

Sartorial Details

Full Canvas Construction

A sartorial jacket - or coat - needs an interlining that will help give it shape and mold it. Canvas gives the item a tailored and crafted look. In short, it breathes life into it. Purely technical, canvas is made from either horsehair, wool, mohair or camel hair. It could also be a mix of them all, with varying thickness and weight. The canvas is stitched to the jacket, often by hand, thus making the canvas pieces 'floating' in the middle of the inner and outer cloth. This gives the jacket added flexibility. The canvas runs from the upper parts, all the way down to the end of the jacket. After you wear your canvassed suit for a while, it will begin to take your shape and look incredibly natural.

Roped Shoulders

A roped shoulder - or sleeve - head describes the bumped shape or ridge of the sleeve’s attachment to the shoulder. The higher it is, the more imposing the shoulder line appears. This can often be found in iconic British tailoring.

Handmade Buttonhole

Handmade buttonholes are made using a chain of knotted loops called purl stitches that make them strong and visually distinctive. It takes about five seconds to sew a regular buttonhole with a machine – a single handmade buttonhole takes about 10 minutes to sew.

Two-Button Closure

The jacket has a two-button closure which keeps the profile neat.

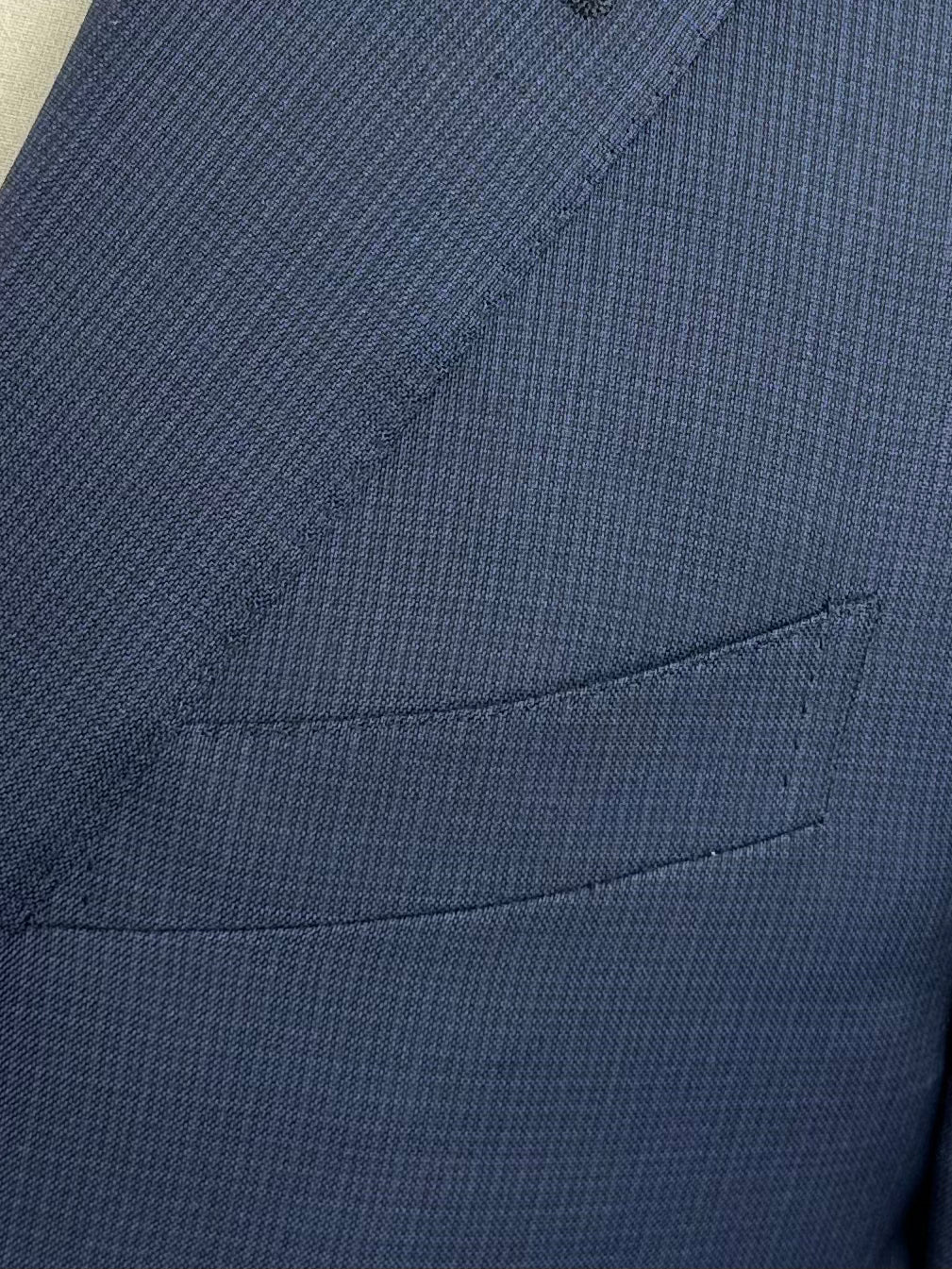

Chest pocket - Rounded welt pocket

Also known as ‘barchetta’ Italian for ‘little boat’, it is so named because this pocket floats on the chest gently angled upward, just like the bow of a sailboat. These pockets echo the lively roll of a lapel that carries the spring of canvas and natural wool, unlike machine-made chest pockets that have a more stamped-out, rectangular shape and less life.

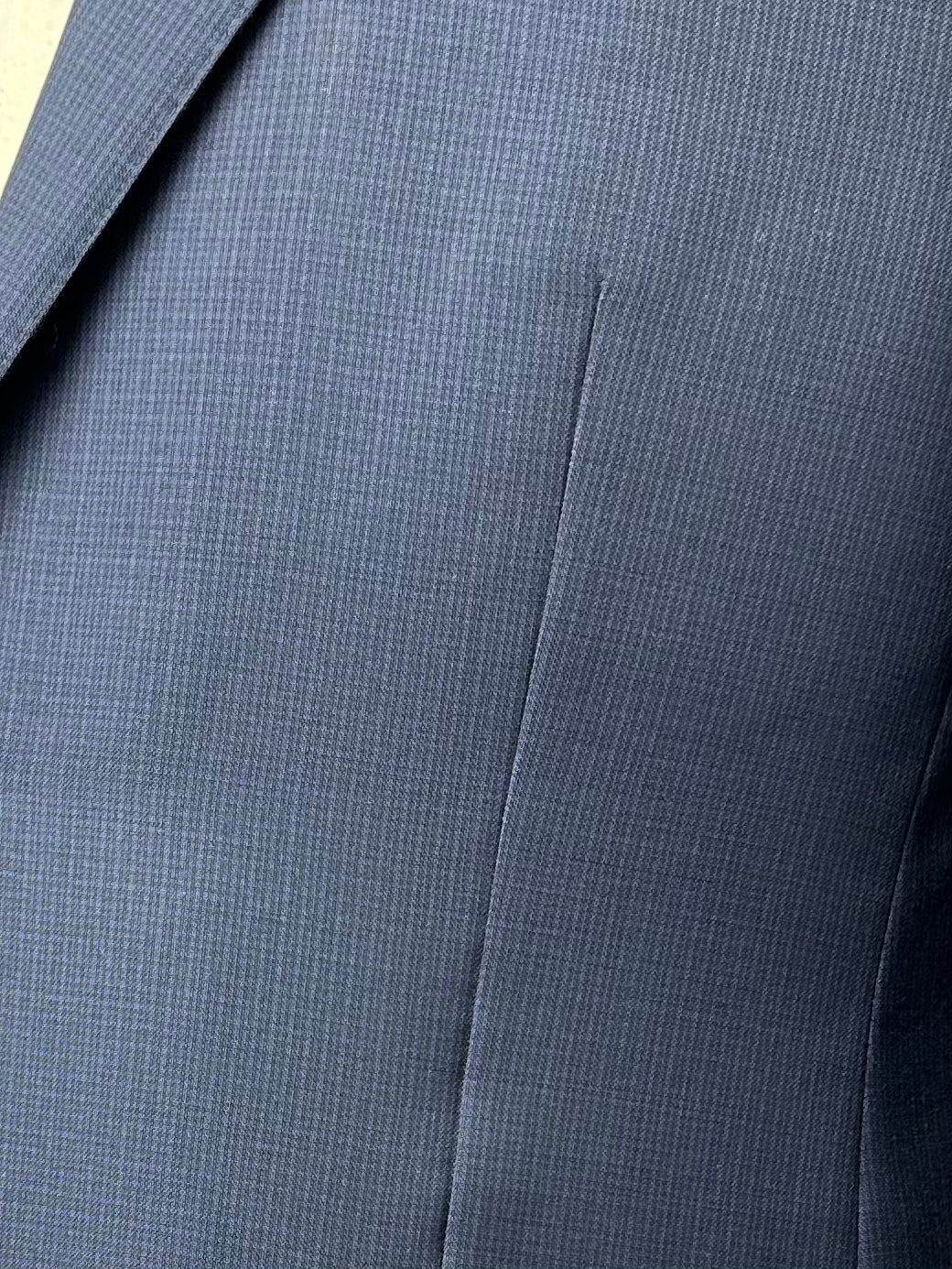

Darts

The tailors adds two darts - think of them as pinched seams - to ensure the jacket’s body achieves a slim silhouette. The process, called mezzo punto riprese, is done entirely by hand.

Horn Buttons

Horn buttons are prized for their quality. They are made with the finest genuine horn material, improving the appearance of the suit. And because they are so strong, you don't have to worry about them cracking or breaking.

Jetted Pockets

The first jacket pockets were sewn inside the lining or seams of garments, and are called “jetted” pockets. In their simplest form, they consist of little more than a slit. Suits that are the most formal, especially tuxedos, have no flap pockets altogether to give the piece a more streamlined look.

size

50 IT / 40 US / Large

Curator's Description

Curator's Description Materials

Materials